|

|

Dictionary of Sharpening Terms |

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z |

| A |

α and β angles

α - alpha. Indicates an angle.

| 1 |

The general use in this Sharpening Handbook is to denote the included angle.

| 2 |

In some cases, α and β may both be used for included angles, but the two are used to denote that they are different parts of the same tool. In such cases, α1 vs. α2 would not be sufficient for explaining what needs to be done.

See also, Hive Tools.

| B |

β - beta. Indicates an angle.

| 1 |

The general use in this Sharpening Handbook is to denote the bevel angle (i.e., 1/2 of the included angle, α).

For single-bevel cutters (e.g., Japanese marking knives and grafting blades & pruning blades on pocket knives), this is the total bevel angle for sharpening.

| 2 |

In some cases, α and β may both be used for bevel angles, but the two are used to denote that they are different parts of the same tool. In such cases, β1 vs. β2 would not be sufficient for explaining what needs to be done.

Bevel Angle - With double-edge cutters (i.e., pocket knives), this is half the angle measured across both sides. The picture above to the right outlines this well.

This is also called, “Degrees per Side” or DPS.

The typical denotion for this is β.

| C |

Clearance angle on a twist drill

Clearance Angle - This term is the angle between the primary and secondary facets on a drill. The ground area allows for clearing out swarf as it is generated during the drilling process.

See also, Twist Drill Bit.

Concave grind

Concave Grind - a grinding profile where the edge has a concavity cut into it by a round grindstone. This profile is sometimes called a “hollow grind”.

More details are at Grind Profiles

Convex grind

Convex Grind - a grinding profile where the edge has a convex surface. This is often preferred for axes and some carving tools.

More details are at Grind Profiles

| D |

Deburring - Remoeval of burrs along the side of a cutting edge. This is commonly associated with saws and garden tools.

Deburring is called Stoning by some authors.

Degrees per Side - see Bevel Angle.

DPS (Degrees per Side) - see Bevel Angle.

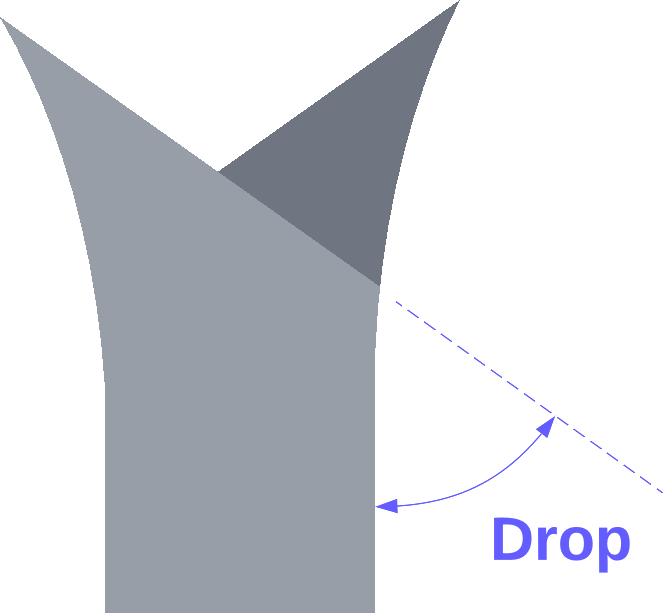

Drop Angle - measure of the angle the file is positioned down from horizontal. This is a measurement needed when sharpening hand saws & saw chains. The picture to the right shows drop as seen from the end of the saw's blade.

Drop is called Slope by some authors.

| F |

Facet - a side, particularly one which gets ground.

File Card - a file card is a special brush used for cleaning a machinist's file.

Flat grind

Flat Grind - a grinding profile where the edge is completely flat. Also known as a Scandi grind.

More details are at Grind Profiles.

Fleam Angle - measure of the angle the file is positioned from the saw blade's edge. This is a measurement needed when sharpening hand saws. The picture to the right shows drop as seen from the top of the saw's blade.

| G |

γ - gamma. Indicates an angle.

| 1 |

The general use in this Sharpening Handbook is for the skew on an cutting edge.

See also, Skew Chisels.

| 2 |

In some cases, it is also used where there is a need for a third angle to be referenced.

See also, Pyramid Point Tools.

Grind Profile - The way the edge is ground when sharpening. Typical profile shapes are a Flat Grind, Concave Grind, or Convex Grind. These can also have a micro-bevel or secondary grind added to them.

More details are at Grind Profiles.

| H |

Hollow Grind

| 1 |

Another term often used for a Concave Grind in grinding the cutting edge.

| 2 |

Some authors denote grinds used to make sharpening easier and faster as hollow grinds (as they leave “hollows” in the surface). In the Sharpening Handbook, these are called Relief Grinds.

Honing - A process by which an edge is refined. This is usually different from stropping. Honing may be done on a very high grit grindstone (e.g., a Japanese waterstone); whilst stropping is done with an edge-trailing action using some other form of grinding media.

Honing is usually proceeded by sharpening, and sometimes followed by stropping.

More details are at General Information on Sharpening Woodworking Bench Tools.

| I |

Included angle

Included Angle - With double-edge cutters (i.e., pocket knives), this is the angle measured across both sides.

The typical denotion for this is α.

| J |

Jointing - A process for making a surface or edge flat and true. This is a process used when sharpening hand saws

JS - Jig Setting.

| K |

Kerf - The width of a saw's cut. This is determined by the saw's Set.

| M |

Flat grind with micro bevels

Micro Bevel - An additional edge added to the primary cutting edge to make resharpening faster & easier. The micro bevel also strengthens the cutting edge as it is not as acute.

The angle for the micro bevel is typically 2° to 5° higher than the edge angle.

More details are at Micro Bevels.

| P |

Point angle on a twist drill

Point Angle - This term is the angle of the two facets at the end of the drill.

See also, Twist Drill Bit.

This term is also used for the angle at the nose of the cutter. This is typically used when discussing knives, especially marking knives.

See also, Marking Knife.

Primary Bevel - The edge grinding performed first. This is a common term applied to the use of a round grindstone when first setting the angle on a chisel or plane blade. (See also, Secondary Bevel)

Profile (Grind) - The way the edge is ground when sharpening. Typical profile shapes are a Flat Grind, Concave Grind, or Convex Grind. These can also have a micro-bevel or secondary grind added to them.

More details are at Grind Profiles.

Projection - The distance a tool projects beyond the jig holding the tool.

The typical denotion for this is P.

| R |

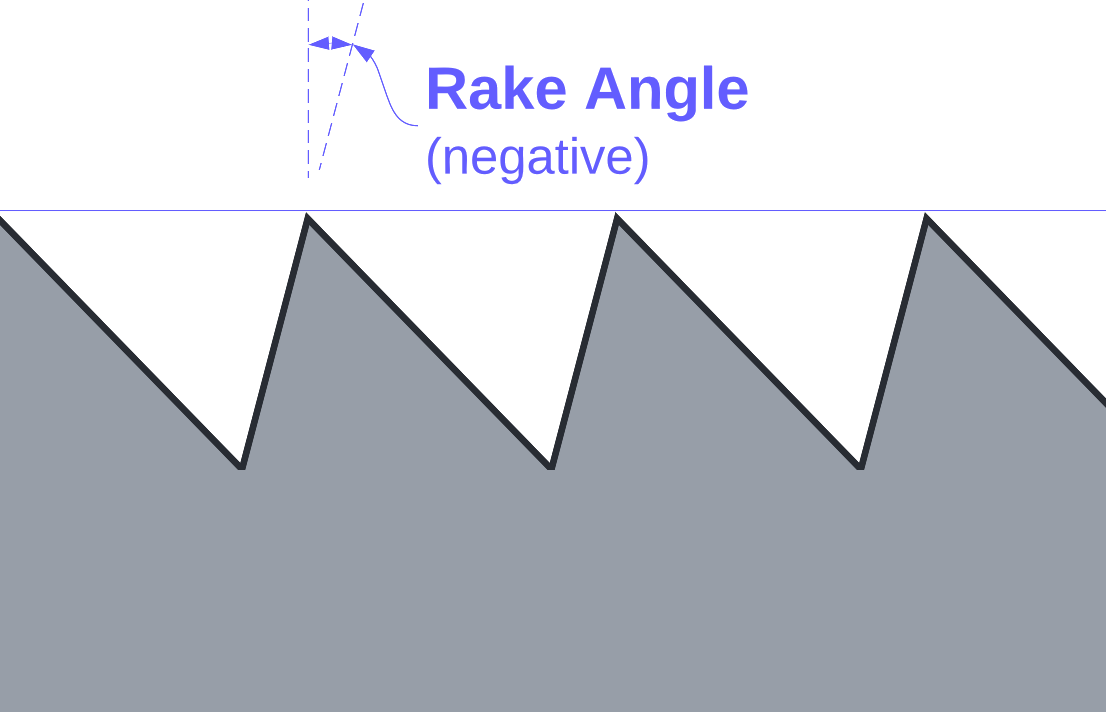

Rake Angle - the measure of the cutting edge away from vertical. Based on the picture to the right, a positive rake angle has he teeth leaning towards the left, and a negative rake angle has the teeth leaning to the right. This is a measurement needed when sharpening many tools. The picture to the right shows drop as seen from the side of a saw's blade.

A negative rake scraper employs such an angle for the top edge.

Such angles are also quite critial for metal lathe tooling.

Relief

| 1 |

A grind added to a cutting edge so that the tool has room to work without an unused part of the tool getting involved. The picture to the right shows a metal lathe cuttoff tool and the relief ground into the front edge.

See also, Wood Lathe Bowl Gouges & Metal Lathe Tools.

| 2 |

A grind added to a larger surface to make the resharpening easier and faster. This is very typical with the backs of Japanese Wood Chisels. Garret Hack recommends this for traditional wood chisels also.

See also, Woodturning Vortex Tools.

| S |

Saw Jointer - a tool used to file the tops of a saw's teeth to ensure they are all aligned. This is a tool used when sharpening hand saws. Lee Valley sells a good Jointer/Edger made by Veritas.

Saw Set - a tool used to bend the teeth on a saw, to set the angle. This is a tool used when sharpening hand saws. (See also, Set)

Saw Vise - a tool used when sharpening a hand saw. A good one holds the saw rigidly, preventing it from vibrating when files are used to sharpen the saw. This is a tool used when sharpening hand saws. Gramercy Tools makes a 14” Saw Vise which is quite good.

Scandi Grind - see Flat Grind.

Secondary Bevel - The edge grinding performed second. This is a common term applied to the use of a flat grindstone when setting the edge angle on a chisel or plane blade. (See also, Primary Bevel)

Sometimes this is a term used to mean the micro bevel.

Secondary Point Angle (SPA) - For tougher materials, an SPA is useful for reducing the stress on the outside cutting lip corners. SPAs can be added to extend drill life, improve hole finish and minimize the exit burr on through-drilled holes.

Experience in using larger drill bits shows that SPAs help to reduce wander when drilling deep holes. These extra facets cause the drill to have a stronger self centering action and the sharp outer point on the cutting lip is eliminated so the drill remains sharp longer. The chip is weakened by the difference in cutting action between the primary and SPA facets so long spirals are less common because the chips are prone to break. (...) When through drilling the SPA reduces or eliminates the exit burr on most materials.

(Click on the picture to the right to see a larger version.)

See also, Twist Drill Bit.

Set - measure of the amount that a saw's tooth is bent away from the line of the cutting axis. An increased set increases the width of a saw's cut (the kerf). This is a measurement needed when sharpening hand saws.

Shaping - A process by which tool's edge is made to be substantially different (e.g., grinding it from 90° to 45°). Shaping is usually only done once in a tool's life; however it may be necessary if the tool's cutting edge is badly damaged.

Shaping is usually followed by sharpening.

See also, General Information on Sharpening Woodworking Bench Tools.

Sharpening - A process by which an edge is made ready for use. This step gets repeated often as a sharp tool work better and safer.

Sharpening is typically followed by honing.

See also, General Information on Sharpening Woodworking Bench Tools.

Slope - See Drop.

Stoning - see Deburring.

Stropping - A process by which an edge is polished. This is usually different from “Honinga>” and is the final step in making a highly sharpened edge. Honing may be done on a very high grit grindstone (e.g., a Japanese waterstone); whilst stropping is done with an edge-trailing action using some other form of grinding media. Examples of such media include diamond powder added to a felt wheel, or grinding rouge added to an MDF shape.

Stropping is usually proceeded by Honing.

See also, General Information on Sharpening Woodworking Bench Tools.