|

|

Grind Profiles |

The shape of the grind cut into a tool is a decision best made by the individual using the tool, based on their own experience. That said, some general guidance regarding profiles is below.

The pictures of the grind profiles are exaggerated to help with communication. They do not reflect the actual amount of concavity or convexness.

Double Bevel |

Single Bevel |

Recommended For

|

This bevel shape does provide a good guide to stabilize the cutting action, however it is so long that it may be difficult to pull out of the cut (i.e., for stop cuts).

It can be double-beveled as shown in the upper picture, or have a single bevel as shown in the lower picture.

When single beveled, this is commonly called a “chisel grind”. These are not common, except for fine-cutting knives like sushi or grafting knives. And, they can be made for either left or right handed use.

Dr. Larrin Thomas noted in his book, Knife Engineering: Steel, Heat Treating, and Geometry (2025),

(Single bevel blades) are used in many sushi knives due to the consistent type of cut that is performed. The chisel grind makes controlling the direction of cutting difficult, but sushi is cut in the same direction each time. And the single bevel pushes the material in only one direction as well. Sushi knives usually have a hollow opposite the evel, which helps prevent sticking and reduces drag ...

If you use a flat grind, then consider using a slightly lower value for α.

This YouTube video discusses using the Tormek MB-100 Muti Base for achieving a flat grind using the side of the grinding wheel. The diamond grinding wheel is recommended; however I have used the MB-100 on the SB-250 and SG-250 grindstones.

Using the side of the grinding wheel is also key when flattening the back of a single beveled blade.

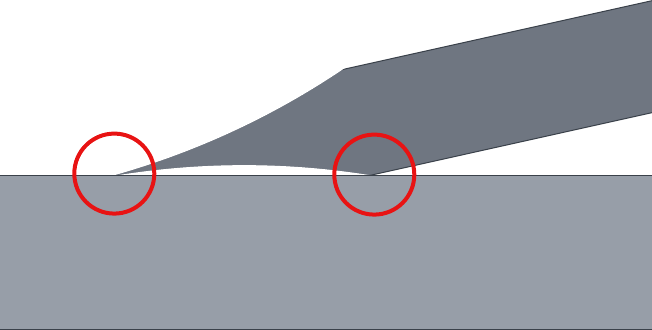

When using flat stones for final sharpening (e.g., grits >2000), a hollow grind can make this easier. As shown in the picture to the left, the two points circled in red provide positive locations for setting the grinding action. It also reduces the amount of grinding needed as there is less metal meeting the grindstone.

Double Bevel |

Single Bevel |

Recommended For

|

This is the grind achieved when using the perimeter edge of round grindstones (e.g., on a Tormek), though the concavity is quite small, especially on such a small grinding surface width. As an example, for a 2mm thick blade sharpened at an α=20°, the concavity is approximately 0.02mm (0.001”).

Some carvers do not like to use concave grinds; however many have found that for some operations like wood turning, the concavity really does not matter for their work, and that fhe concavity makes for honing an edge in a much easier manner (I.e., the concavity allows the edge to be balanced easily on a flat, high grit stone). This is especially a useful process for plane blades and bench chisels.

(The picture is certainly exaggerated for the amount of concavity.)

Double Bevel |

Single Bevel |

Recommended For

|

This grind is not recommended for the general carving knife; however it is recommended by some for chip carving. It does allow for great flexibility; however it does not provide adequate anchoring for the cutting action.

Dr. Larrin Thomas noted in his book, Knife Engineering: Steel, Heat Treating, and Geometry (2025),

... one benefit of a convex grind is that when cutting soft materials, the material is “pushed” away from the knife, which is a promoted benefit of convex-ground kitchen knives ...

A convex grind is commonly found on the tips of knife blades where the blade is expected to see high lateral forces (e.g., tactical knives).

Flat with Micro-Bevel |

Concave with Micro-Bevel |

Convex with Micro-Bevel |

Recommended For

|

Micro-bevels could be applied to any of the above-listed grinds; however it is most common with Scandi/Flat grinds and Concave Grinds.

Many carvers do not like to use a carving knife with a micro bevel grind. Their argument is that it does not give them a large enough bevel for anchoring the cut; however if the bevel on the micro-bevel is long enough, it is quite usable. Also, this grind shape allows for great flexibility.

(Additional notes are also available on a different web page for Micro / Secondary Bevels.)