|

|

Pyramid Point Tool |

Edge angle

Point tool

The Pyramid Point Tool is ground with 3 cutting edges, each very much like the vortex tool.

|

For the artisan, craft is an end in itself. For you, the artist, craft is the vehicle for expressing your vision. Craft is the visible edge of art. David Bayles |

|

General Guidelines |

|||

|---|---|---|---|

| β |

Sharp

|

Comments |

|

| 15° - 20° |

|

Some turners will increase β to be as high as 45°. That will work for some activities such as rolling a bead, but does not provide access into tight areas necessary for turning beads (especially smaller ones). I find the recommended angle (β) to be better for such work. And if you are new to this tool, learning to use it at that angle will provide for more options as you improve. The Projection Calculator on this site can be used to calculate settings for different values of β. This calculator is web-based and does not require Excel. |

|

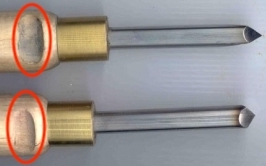

Nut used for alignment when shaping and sharpening

Before the first shaping of this tool, look at how you can make the re-sharpening repeatable with minimal effort.

I found one recommendation for gluing a nut to the tool at the ferrule. (If you are making your own tool, consider using a nut for the ferrule.) There is circled in red in the picture to the left. Three of the nut's sides provide a great reference for ensuring the edge is presented to the grindstone consistently.

I used 2-part epoxy to attach a 1/2” nut to mine as the tool had a shaft of that size.

I had to drill the nut's threaded area out a bit to enable it to fit over the tool's shaft. The minor diameter for some options are:

Groove cut and used for alignment when shaping and sharpening

David Reed Smith published an article describing how to make these, but alas it is no longer available on the Internet. In that article, he noted that adding a groove to the handle helped with aligning it when sharpening the tool.

This would be particularly useful if sharpening on the Tormek as the groove could be aligned with the universal support bar.

This tool is one where reshaping the cutting surface can be onerous, and the Tormek BGM-100 Bench Grinding Mounting Set can be quite useful. When grinding on a high speed grinder, all the settings remain the same.

Sean Rubino's video below shows how to make a point tool, and it is quite good. The jig that Sean made is worth considering for sharpening this tool. If you do make one of these jigs, consider making it from metal (e.g., aluminum). And add a brass tipped set screw to help keep the tool from rotating in the jig when sharpening the other three faces.

Sharpness scales (as shown in the grey icon to the left) are used to indicate the recommended sharpness for the blades noted above. You can click on any of the icons showing the sharpness scale and be redirected to the page describing this more. Lower numbers are duller; higher numbers sharper.

These are general recommendations; you will need to use your own judgment, based on the knive’s intended purpose.