|

|

Twist Drill Bit |

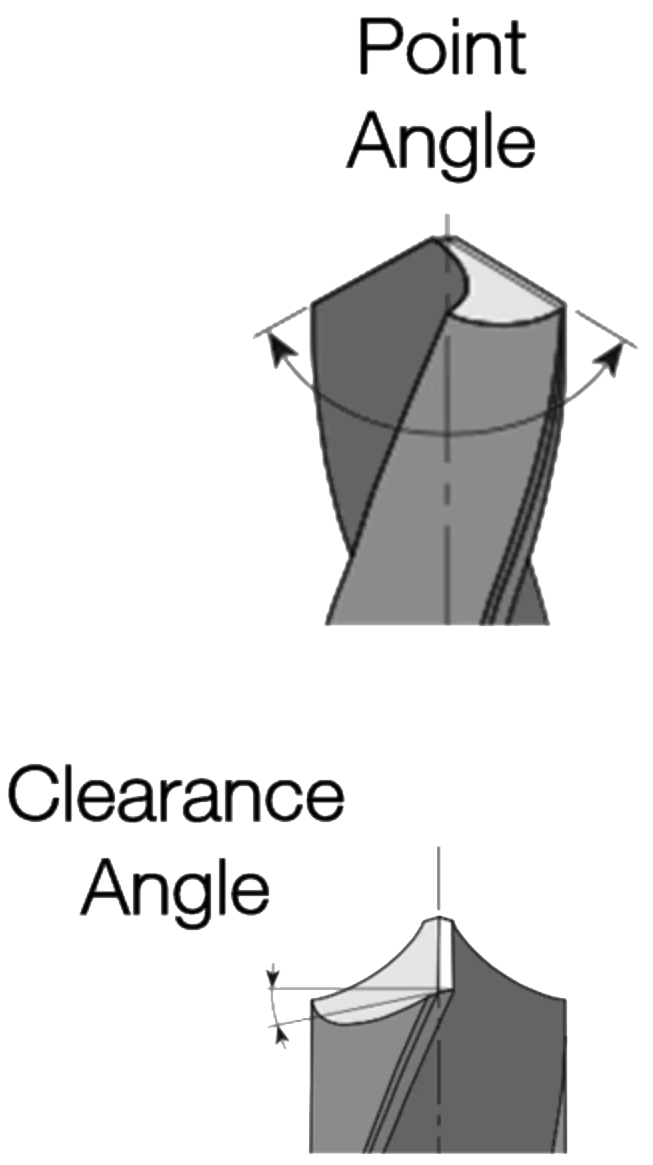

Key Angles

Terminology for multi-faceted grinds

Twist drill bits are sharpened according to the table below.

The Tormek DBS-22 Drill Bit Sharpening Jig works very well for those drill bits. That jig can hold bits in the range of 0.125” - 0.875” (3 - 22 mm).

|

No matter how many times I cut this, I can't get it long enough! Unknown Old Machinist |

Notes:

|

General Guidelines for 4-Facet Grind |

|||||

|---|---|---|---|---|---|

|

Material Type |

Point Angle |

Clearance Angle |

Notes |

||

|

Recom. |

Range |

Recom. |

Range |

||

| Aluminium | 118° | 90° - 130° | (as above) | 12° - 15° | Clearance angles based on drill bit size should be used. |

| Armour Plate | 135° | 135° - 140° | 7° | 6° - 9° | |

| Brass | 118° | 118° | (as above) | 12° - 15° | Clearance angles based on drill bit size should be used. |

| Bronze | 118° | 110° - 118° | (as above) | 12° - 15° | Clearance angles based on drill bit size should be used. |

| Bronze, High Tensile | 105° | 100° - 110° | (as above) | 12° - 15° | Clearance angles based on drill bit size should be used. |

| Cast Iron, Soft | 95° | 90° - 100° | (as above) | 12° - 15° | Clearance angles based on drill bit size should be used. |

| Cast Iron, Medium | 105° | 100° - 110° | (as above) | 12° - 15° | Clearance angles based on drill bit size should be used. |

| Cast Iron, Hard | 110° | 100° - 118° | 9° | 8° - 12° | |

| Cast Iron, Chilled | 118° | 118° - 135° | 7° | 5° - 9° | |

| Copper | 118° | 100° - 118° | 14° | 12° - 15° | |

| Iron, Malleable | 95° | 90° - 100° | 14° | 12° - 15° | |

| Magnesium and Alloys | 95° | 70° - 118° | 14° | 12° - 15° | |

| Monel Nickel | 120° | 118° - 125° | 11° | 10° - 12° | |

| Nickel Alloys | 135° | 135° - 140° | 7° | 5° - 7° | |

| Plastic, Hot Set | 90° | 60° - 90° | 11° | 10° - 12° | Minimum point angle on the Tormek DBS-22 Drill Bit Sharpening Attachment is 90°. |

| Plastic, Cold Set | 125° | 118° - 135° | 14° | 12° - 20° | |

| Steel, Low Carbon | 118° | 110° - 118° | 9° | 7° - 9° | |

| Steel, Medium Carbon | 118° | 118° - 125° | 9° | 7° - 9° | |

| Steel, High Carbon | 130° | 118° - 145° | 9° | 7° - 9° | |

| Steel, Forged | 130° | 118° - 145° | 11° | 7° - 12° | |

| Steel, Alloy | 118° | 118° - 125° | 11° | 10° - 12° | |

| Steel, Stainless | 115° | 110° - 118° | 11° | 8° - 12° | |

| Steel, Stainless, Hard | 125° | 118° - 135° | 7° | 6° - 8° | |

| Steel, Manganese | 145° | 140° - 150° | 9° | 7° - 10° | |

If you pursue sharpening small bits (< 1/8 in / < 3.0 mm),

Addition of a tertiary facet can be useful for helping to remove waste as the hole is drilled. There is no guidance on the angle for these; only that they need to be greater than the secondary facets. If an angle is needed:

The Tormek DBS-22 Drill Bit Sharpening Attachment is not designed for a 6-facet grind, so values are not shown for it. A modification to the DBS-22 was made by Janne for 6-facet grinding, and more information can be found on the Tormek Forum.

For tougher materials, an SPA is useful for reducing the stress on the outside cutting lip corners. (This is well outlined in Joseph Mazoff's document {see below}.) However, the Tormek DBS-22 Drill Bit Sharpening Attachment is not designed for a grinding SPAs, so it is not outlined here.

Experience in using larger drill bits shows that SPAs help to reduce wander when drilling deep holes. On GadgetBuilder's web site (referenced below), it was noted:

These extra facets cause the drill to have a stronger self centering action and the sharp outer point on the cutting lip is eliminated so the drill remains sharp longer. The chip is weakened by the difference in cutting action between the primary and SPA facets so long spirals are less common because the chips are prone to break. (...) When through drilling the SPA reduces or eliminates the exit burr on most materials.

Again, on GadgetBuilder's web site, it was noted:

Secondary Point Angles (SPAs) can be added to extend drill life, improve hole finish and minimize the exit burr on through-drilled holes.

Notes:

Sharpness scales (as shown in the grey icon to the right) are used to indicate the recommended sharpness for the blades noted above. You can click on any of the icons showing the sharpness scale and be redirected to the page describing this more. Lower numbers are duller; higher numbers sharper.

These are general recommendations; you will need to use your own judgment, based on the knive’s intended purpose.