|

|

Wood Carving Chisel |

Single bevel edge angle

Guidelines shown below are for the cutting edge angle. Since this the entirety of the blade's cutting edge is honed, no secondary / micro bevel is given (as with Bench Chisels).

The angle (α) is the effective grind angle at the chisel point. The angle measured with the Tormek WM-200 AngleMaster will be greater than α, but only by a very small amount.

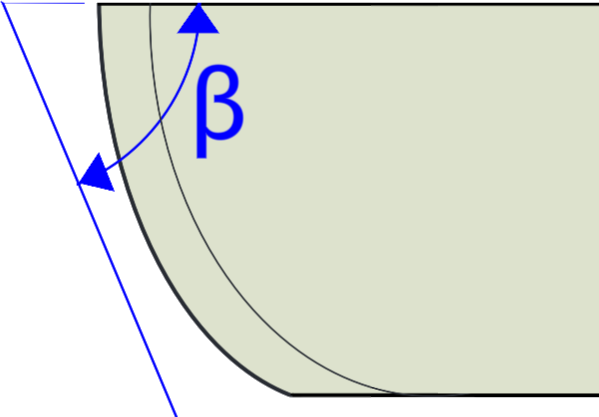

Skewed end of the chisel with a convex edge

If this chisel is to have a skewed end (as shown to the left), it is recommended that β not be greater than 20° unless you area aiming for a more Scandinavian style grind which can be up to 35°. A greater skew angle may tend to cause the chisel to drift to the side when using it.

|

The Christian shoemaker does his duty not by putting little crosses on the shoes, but by making good shoes, because God is interested in good craftsmanship. Martin Luther |

Lara Reisigl Domeneghetti wrote a great article (see also, below) regarding the Scandinavian grind. In it, she recommended a convex curved edge as shown in the image to the left.

Carving edges are typically not reground; only to reshape them, or repair a problem with the edge. More commonly, the edge is simply honed on the leather wheel.

Hollow grinding on the back of the bench chisels (traditional, not Japanese chisels) is recommended by some, including by Garret Hack. Two videos below show that process.

Sharpness scales (as shown in the grey icon to the left) are used to indicate the recommended sharpness for the blades noted above. You can click on any of the icons showing the sharpness scale and be redirected to the page describing this more. Lower numbers are duller; higher numbers sharper.

These are general recommendations; you will need to use your own judgment, based on the knive’s intended purpose.

SE-77 Square Edge Jig

SE-77 square edge jig Some have mentioned that it is a bit tricky to get the alignment correct for chisels using this jig. That said, this jig is very useful for cambering plane blades, so it is useful to have if you sharpen those also. Shorter chisels won't always work in this jig. The MB-102 Multi Base can alleviate this issue. If you have some of your grandfather's old chisels around which you want to use (other to open paint cans), consider using

|

SE-76 Square Edge Jig

SE-76 square edge jig This is a great jig to use for sharpening chisels, including skewed edges. However shorter chisels won't always work in this jig. If you have some of your grandfather's old chisels around which you want to use (other to open paint cans), consider using the SVH-60. As with the SE-76, shorter chisels won't always work in this jig (unless using the MB-102 Multi Base). Consider using

The SE-77 has replaced this jig and the SE-76 is hard to find. |

SVS-38 Short Tool Jig

SVS-38 short tool jig This jig is also useful for sharpening chisels where there is not enough length to use either of the two jigs listed above. |

SVH-60 Straight Edge Jig

SVH-60 straight edge jig This is the original jig for sharpening chisels and plane blades. It is no longer being made which is unfortunate as it is really great for holding shorter chisels. If you have shorter chisels, consider getting one from the used tools market. The SE-77 has replaced this jig and the SVH-60 is hard to find. |

SVD-110 Platform Jig

SVD-110 platform jig The platform jig will probably be more useful for sharpening blades with curved cutting edges. If sharpening this tool often, consider dedicating a USB and platform jig (SVD-110) to this. This approach is shown in this web page, and enables the carver to resharpen the tool quickly and get back to carving. |

Projection Jig for the SE-76 or SE-77The Projection Jig for the SE-76 or SE-77 is used with the TTS-100 for quickly setting both the USB height and the projection of the tool from the SE-76 or SE-77 jig. |

A good source for the shape of a handle is The Wood Turner's Handy Book (1887), by Paul N Hasluck (see pg. 67, fig. 39).

Another source is the series of articles written by Aaron Keim, Making a New Chisel Handle for Tired Hands, (see details below).

|

|

Ian recommends that the cutting edges be ground to 10° on both sides of the cutting edge, resulting in an α of 20°. The resulting edge looks rather like a knife. Pictures in the article explain this better.

This approach is quite different from others I've read, especially for gouges and V-tools.

Aaron noted, “Some of the most important tools in my shop are my chisels. Whether I am chopping, carving, or paring, they are in my hands all day. As I have gotten older and my arthritis/tendonitis has gotten worse, my needs have changed. In this blog, I will talk about my preferred chisel handle and show how I make a replacement handle to suit my needs.”