|

|

Cold Chisel |

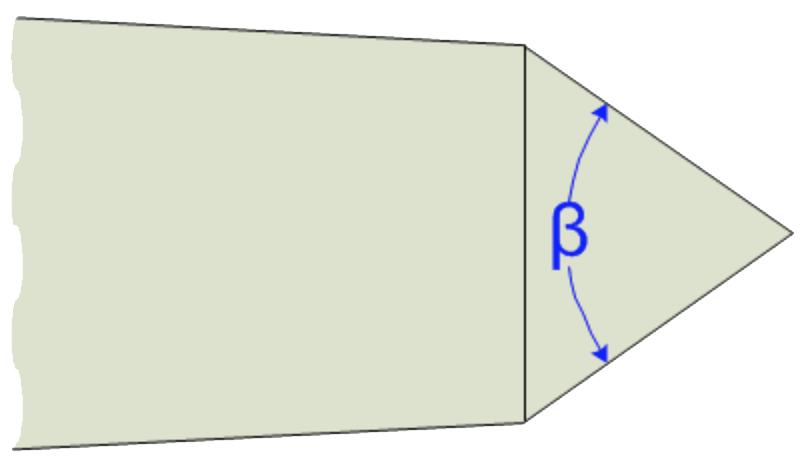

Edge Angle

The Cold Chisel's cutting edge is typically shaped on a bench grinder, though an angle grinder could be used (holding the chisel in a vise). And you can certainly use a file to do this (especially if you have as my father called a, "strong back, weak mind").

The U.S. War Department's TM 9-867 Maintenance and Care of Hand Tools advocates grinding off the corners of the cutting edge so that the cutting edge has a convex shape as shown to the left. This is similar to adding camber to a wood plane's blade.

|

The main rule of this class is to not be a dumbass. Unknown Shop Teacher |

I haven't tried this to gain an understanding of the value. Rather, I see more value in sharpening often.

|

General Guidelines |

|||

|---|---|---|---|

| α |

Sharp

|

Comments |

|

| 60° - 70° |

|

Can be up to 90° if cutting extremely hard metals. |

|

If grinding this on a high speed grinder or sander, be sure to manage the temperature so that the temper is not lost due to overheating.

| High Carbon Steel |

Temperature control is critical for high carbon steel. Tempering will be lost in the steel if heated until it is blue (~550°F / 300°C). Cool by dipping as needed in water. Dr. Larrin Thomas noted in his book, Knife Engineering: Steel, Heat Treating, and Geometry (2025), The lack of sparks or color changes is no guarantee that the edge was not overheated. Therefore, sparks are not necessarily a sign that heat has or has not been generated in the steel. Color changes can occur from overheating of steel in grinding, but during grinding, the surface is being removed, and the affected volume can be relatively small. Therefore a color change is not always observed. Microhardness measurements of edges sharpened with a belt sander show a drop in hardness at edge. This results from “over-tempering” the edge by heating it above its original tempering temperature. |

| High Speed Steel |

Cool by dipping as needed in water. |

| Steel with Carbide Insert |

DO NOT cool by dipping in water. This will cause the carbide to crack due to shocks.

It is also recommended to use a high grit wheel for sharpening carbide as lower grits can cause cracks in the edge leading to it being far more crack-ridden and brittle. (Lower grits can be used for shaping the edge -- see also, Grindstones and Other Sharpening Media - Quick Selection Guide.) |

Sharpness scales (as shown in the grey icon to the left) are used to indicate the recommended sharpness for the blades noted above. You can click on any of the icons showing the sharpness scale and be redirected to the page describing this more. Lower numbers are duller; higher numbers sharper.

These are general recommendations; you will need to use your own judgment, based on the knive’s intended purpose.