|

|

Rotary Cutters |

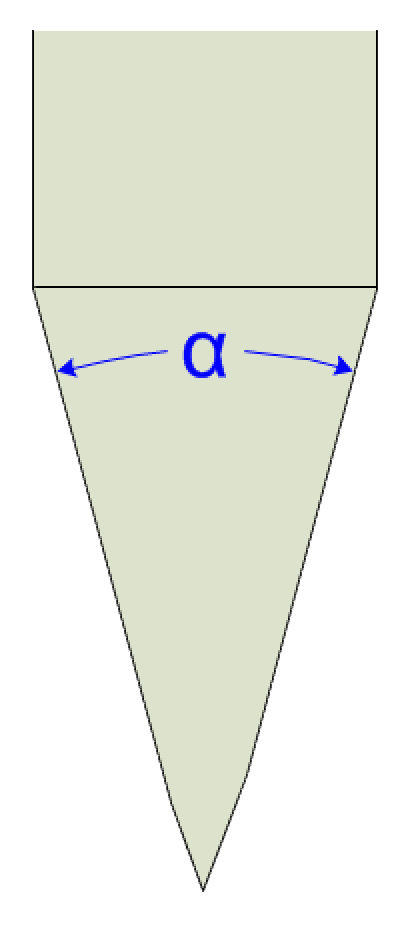

Edge Angle

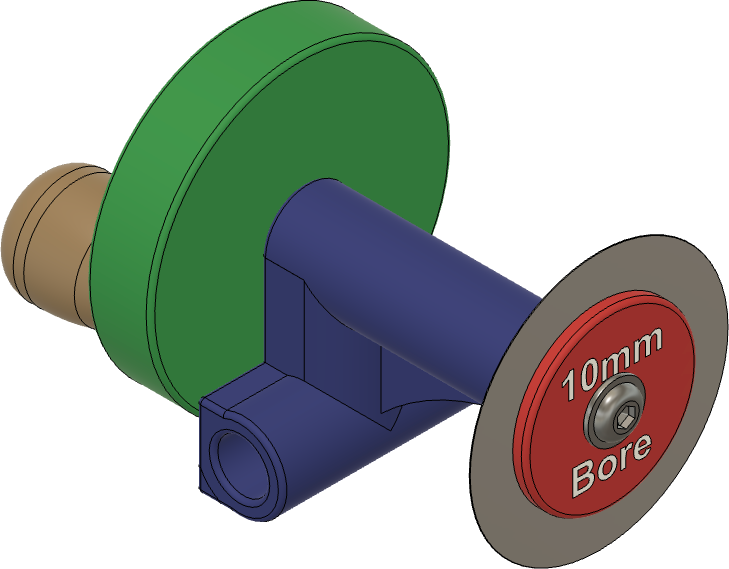

Rotary cutter being held in 3D-printed jig

Wheels on Rotary Cutters are sharpened according to the angles shown below. The calculation of α is measured according to the drawing to the right.

These are sharpened using the a jig which holds the blade securely whilst allowing it to be rotated when being sharpened on the grinding wheel. Consistent speed in the rotation is key to ensuring that the blade does not have any flat spots.

|

To be creative is to let little pieces of your heart go and place them into each project you make. Pat Bravo |

The jig shown above is detailed on the jigs page, Rotary Knife Jig. It is mostly 3D printed so it can be made easily and inexpensively.

Sharpness scales (as shown in the grey icon to the left) are used to indicate the recommended sharpness for the blades noted above. You can click on any of the icons showing the sharpness scale and be redirected to the page describing this more. Lower numbers are duller; higher numbers sharper.

These are general recommendations; you will need to use your own judgment, based on the knive’s intended purpose.

Sharpen the blade using the Tormek DE-250 grinding wheel (1,200 grit). These blades are typically quite hard steel, so the diamond wheel is useful for setting the edge.

Based on how the blade is held it is best to use the USB in the horizontal position. This is edge-leading grinding, so do not be too aggressive with the grinding.

Honing is highly recommended. Feedback from my wife was that the unhoned blade was not sufficiently sharpened.

Honing Wheels

I use paper wheels on a bench grinder, and those work well. A friend made his wheels from MDF, and someone else recommended making them from HDF.

One user of this approach is using the Tormek’s leather honing wheel and PA-70 Honing compound. I cannot speak to how well that works; however I must advise one taking this approach to:

Honing Compound

Hone the blade’s edge using either a diamond paste or honing compound. I have found that these work well:

If using the Tormek leather honing wheel, the PA-70 honing compound should be used.

Holding the Blade for Honing

You can hold the blade using a 10mm bolt with a nut, and rotating it with a battery-operated drill. This is shown in the video noted below.

|

This machine does not have a brain. You must use your own. |

Safety Precautions

|

Make safety a priority: It is not worth the risk.