|

|

Wood Carving Veining Tool |

Edge angle

The Veining Tool's cutting edge is best sharpened in the horizontal position (with the wheel rotating away from the user). This reduces the steel removal rate, and allows for easier sharpening of the edge to the right profile, as it is not too fast.

Guidelines shown below are for the cutting edge angles. Since the entirity of this blade's cutting surface is honed, no secondary / micro bevel is given (as with Bench Chisels).

|

I carve things of wood because things made by effort are more real than things made by wishing. Katherine Arden |

Carving edges are typically not reground; only to reshape them, or repair a problem with the edge. More commonly, the edge is simply honed on the leather wheel.

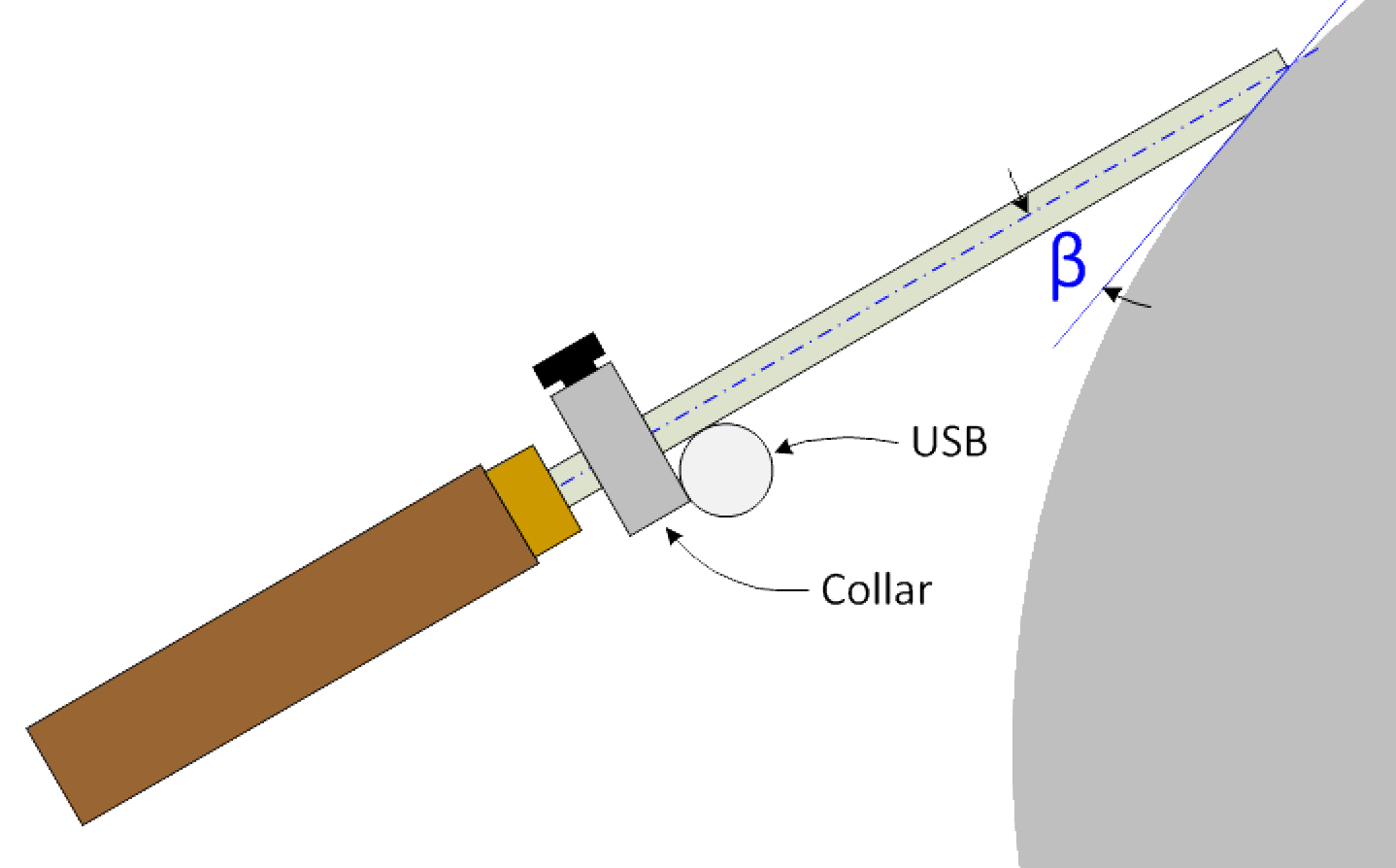

The Tormek SVD-186 or SVD-186 R is the recommended jig. However, for smaller or shorter tools, other jigs may be more useful.

The Tormek SVS-38 or SVS-32 Short Tool Jig may be appropriate. It is used in a similar manner to the SVD-186.

You may need to use a standard, off-the-shelf collar to guide the sharpening process. Most hardware stores carry these, or you can order one such as part number 9414T9 (7/16 inch) or 57485K68 (10 mm) from McMaster-Carr. Note : You will probably need to replace the set screw with a longer one.

Use the Projection Calculator to set the projection and USB distance from the grindstone. This calculator is web-based and does not require Excel.

Sharpness scales (as shown in the grey icon to the left) are used to indicate the recommended sharpness for the blades noted above. You can click on any of the icons showing the sharpness scale and be redirected to the page describing this more. Lower numbers are duller; higher numbers sharper.

These are general recommendations; you will need to use your own judgment, based on the knive’s intended purpose.

A good source for the shape of a handle is The Wood Turner's Handy Book (1887), by Paul N Hasluck (see pg. 67, fig. 39).

Another source is the series of articles written by Aaron Keim, Making a New Chisel Handle for Tired Hands, (see details below).

Ian recommends that the cutting edges be ground to 10° on both sides of the cutting edge, resulting in an β of 20°. The resulting edge looks rather like a knife. Pictures in the article explain this better.

This approach is quite different from others I've read, especially for gouges and V-tools.

Aaron noted, “Some of the most important tools in my shop are my chisels. Whether I am chopping, carving, or paring, they are in my hands all day. As I have gotten older and my arthritis/tendonitis has gotten worse, my needs have changed. In this blog, I will talk about my preferred chisel handle and show how I make a replacement handle to suit my needs.”