|

|

Spindle Roughing Gouge |

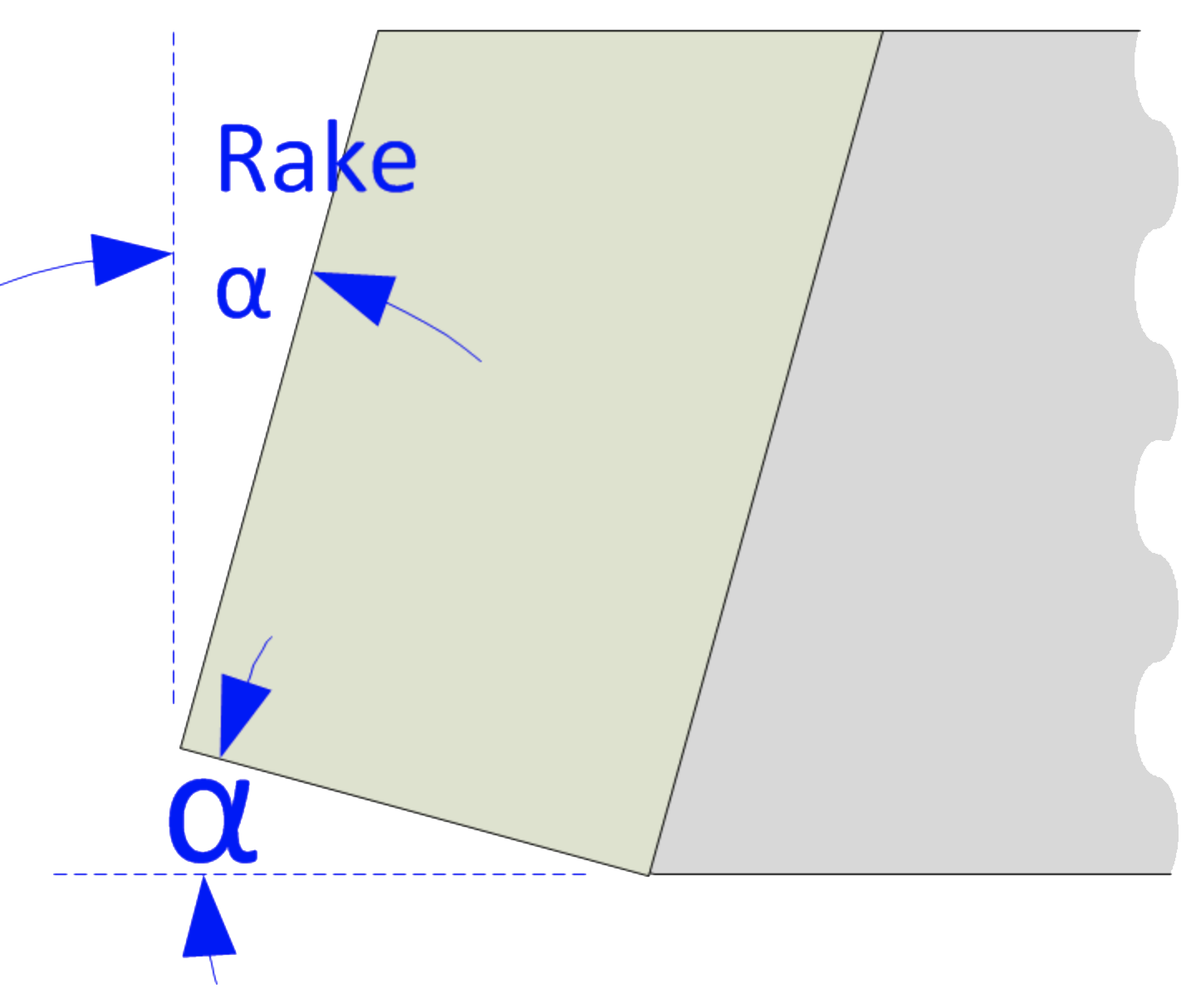

Edge angle

A positive rake angle is recommended by many as it reduces the chance to grab.

Be sure not to have the top of the curve to project forward from the center. To help with this, rotate in one direction only. Between rotations, lift the edge from the stone surface. This prevents working the centre more than the top edges.

Grind until you feel a burr raised along the entire edge, then hone the gouge to remove the burr.

|

Every woodworker needs a fireplace. Unknown |

|

General Guidelines |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Edge |

Rake |

Tormek Jig |

JS |

P |

TTS-100 Hole |

Sharp

|

Comments |

|||

| α |

Range |

β |

Range |

|||||||

| 45° | 35° - 45° | 20° | 0° - 25° | SVD-186 | 0 | 65 mm | A |

|

JR DUBUY on the Tormek forum recommended using the Tormek SVD-186 Gouge Jig with these settings. It works quite well. |

|

| 35° | 35° - 45° | 20° | 0° - 25° | SVS-50 Open Seat | 0° | 55 mm | B |

|

Alan Batty recommended 45°, and this is generally recommended by many. I certainly recognize Mr. Batty's proven experience, but I've found that the 35° realized with these Tormek settings works extremely well. Use with the Tormek SVS-50 Multi Jig with the Open Seat. |

|

Marty Kiminsky noted that an Edge α of 40° to 45° is generally recommended for this tool, and that his personal preference is 40°. See also, "Woodturning" magazine, issue # 352.

Sharpness scales (as shown in the grey icon to the left) are used to indicate the recommended sharpness for the blades noted above. You can click on any of the icons showing the sharpness scale and be redirected to the page describing this more. Lower numbers are duller; higher numbers sharper.

These are general recommendations; you will need to use your own judgment, based on the knive’s intended purpose.

|

|