|

|

Projection Jig for the SE-76 or SE-77 |

I made these pieces using my 3D printer to make it easy for quick-and-dirty resharpening of my chisels when using the Tormek SE-76 or SE-77 jigs. The concept is that the distance from the USB to the grindstone is set using the B hole in the Tormek TTS-100, and the tool projection is set using this jig.

Settings for projection when using the SVD-186 are also available so that this can be used for both jigs.

Special thanks are due to Jan H (jvh on the Tormek Forum, and developer of TormekCalc2) for calculating the projections necessary for the SE-77 using parametric CAD.

Full set |

Aligning a plane blade |

Aligning a chisel |

Aligning a skew chisel |

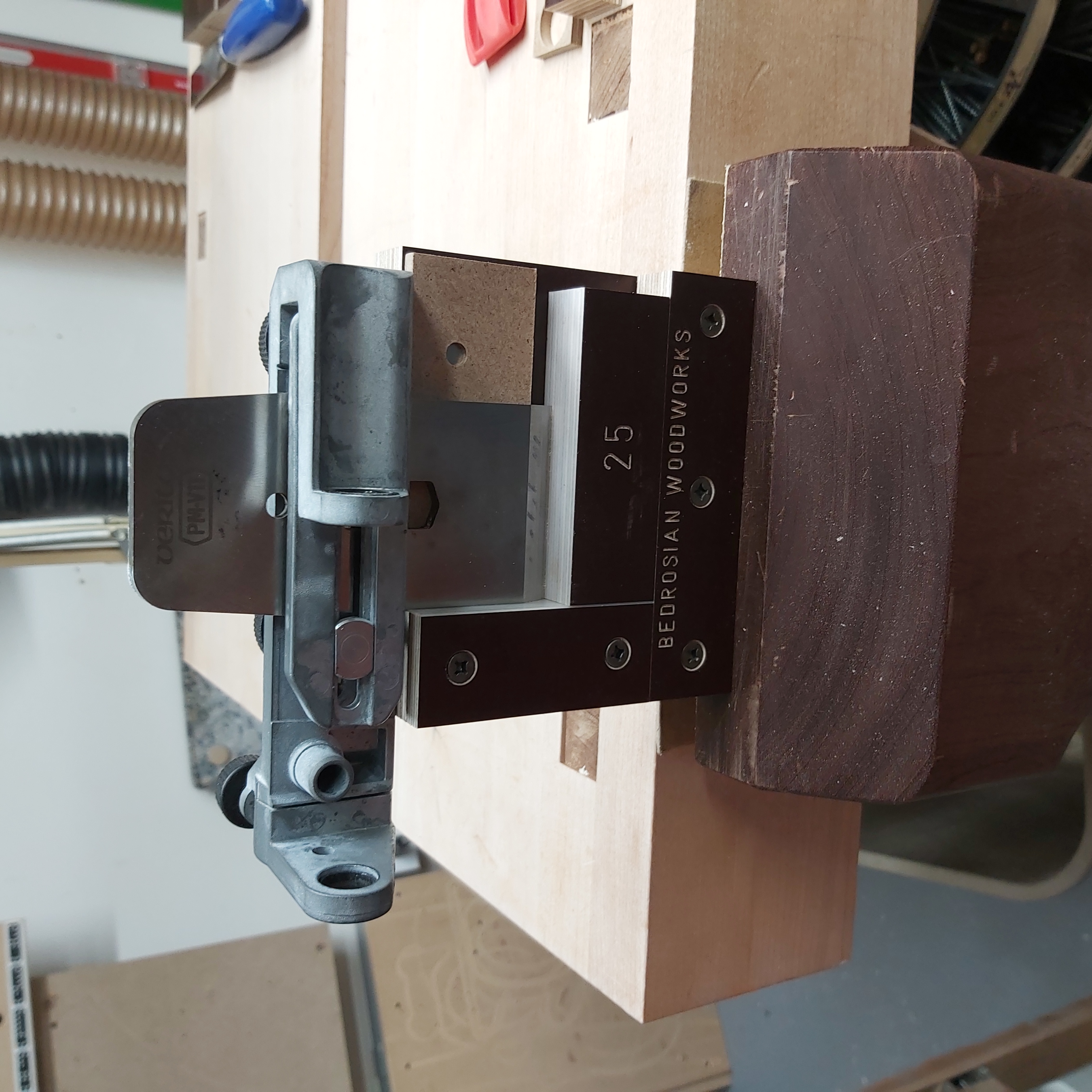

David Bedrosian of Bedrosian Woodworks designed a variation of this which uses magnets to hold parts in place. It is a really innovative approach.

He sells the jig or plans for the jig, and you can get them by contacting him at his eMail: bedrosianwoodworks at gmail dot com (not a link; just blue to highlight it) or DM him on Instagram @BedrosianWoodworks.

There is link to his YouTube video below which shows how he uses this jig.

You can click on any of the pictures from David and see a bigger version.

The steps for using this jig to sharpen a tool are:

The video referenced below, Jigs for the Tormek SE-77, shows the steps for this jig is used.

For the SVD-18x* jig, the right side of this jig has the same projection distances as the TTS-100. It is repeated here for convenience.

The steps for using this jig to sharpen a tool are outlined below. The jig setting and projection are based on your desired grind, and are outlined in the user manual for your SVD-18x jig.

You can purchase one of the 3D-printed versions from Colvin Tools.

You will need to contact David Bedrosian to purchase his (or the plans for making it).

This file is available for printing as a single piece or two.

The jig I originally made is two pieces as that is easier to 3-D print on my older, Creality Ender 3 printer.

|

Two-Piece Design |

|

|---|---|

|

Part |

STL File |

| Part 1 - Top Plate | TTS-100 ProjJig - Part 1.stl |

| Part 2 - Bottom Hook | TTS-100 ProjJig - Part 2.stl |

If you would prefer to print a single file, this one is available. It also includes the text as objects so multiple filament printers can print the text as a different color.

The Fusion 360 file (f3d) is also supplied in case you would like to modify this design for different uses.

|

One-Piece Design |

||

|---|---|---|

|

Part |

3MF File |

F3D File |

| Jig with Text | TTS-100-ProjectionJig-v2.3mf | TTS-100-ProjectionJig-v2.f3d |

This video also reviews how to use this jig.