|

|

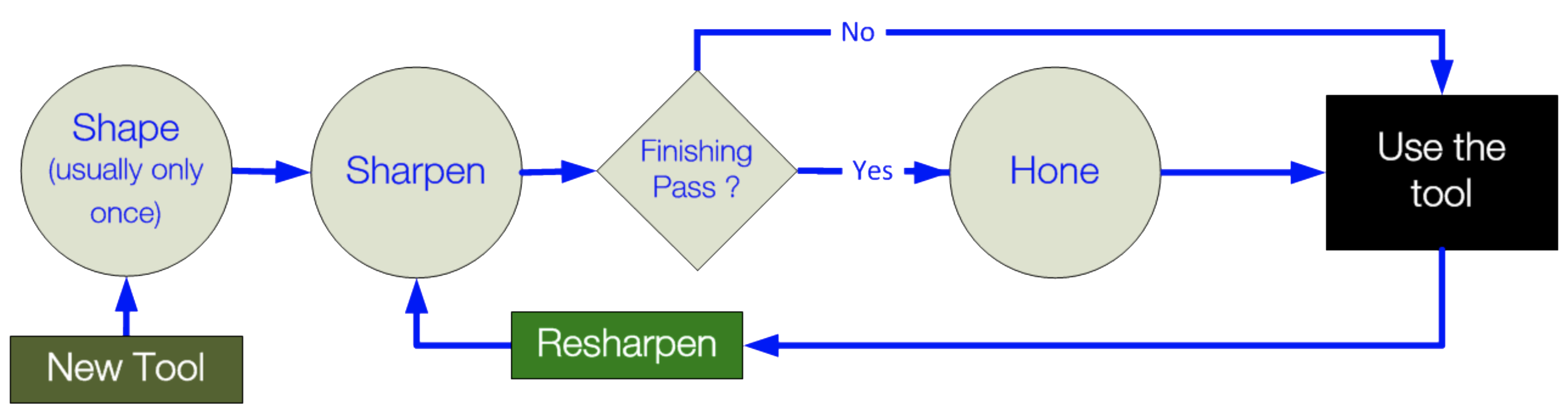

General Information on Sharpening

|

|

Typical Grinding Media Used

Shaping the ToolWood turning tools are typically only (re)shaped once in their lifetime. And that happens when the turner gets the tool from the manufacturer, and adjusts it to their own preferences. |

|

Typical Grinding Media Used

Sharpening the ToolWood turning tools should be resharpened often. Softer woods like cedar don't require that the tool is resharpening as often; but harder woods definitely necessitate the need to be resharpened often. Some turners resharpen as frequently as every 10 or even 5 minutes.And of course, the tool must be resharpened whenever the turner accidentally pushes into the chuck or drops the tool (as it always lands point down !). |

|

Typical Grinding Media Used

Honing the ToolMany turners do not hone their turning tools.Then there are others who sharpen and hone; and then they re-hone again as much as possible (rather than resharpening each time). Alan Lacer is a proponent of this approach, using a diamond plate. You can see that demonstrated in the video below by Mark Baker. My experience has been that rough turning can be done using a tool which is not honed; however the final cuts should be done with a tool which is honed. This provides for a smoother surface which requires less sanding (as sanding is the verb form of a 4-letter word !). Also, a well honed tool surface is a great benefit for woods with tight grains or which are very hard. Note: When honing or stropping, the side to start on is the one where the grinding was last done. If you start on the other side, the burr will get ripped off and you will probably have to re-grind the edge. Dr. Larrin Thomas’ book, Knife Engineering: Steel, Heat Treating, and Geometry (2025), discusses burr removal quite well. |

|

|

|

AAW Total Experience Woodturning Tip: Honing Tips with Mark Baker from AAW on Vimeo. |