|

|

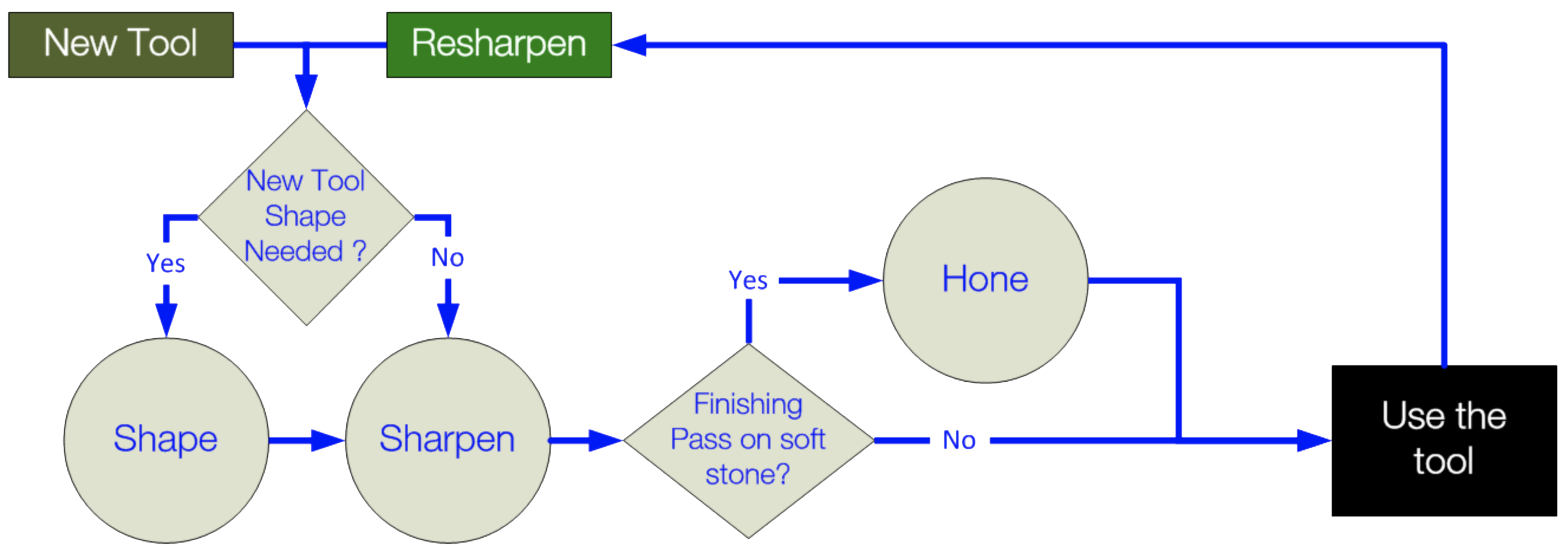

General Information on Sharpening

|

|

Typical Grinding Media Used

Shaping the ToolStone working tools are reshaped based on their need (as dictated by the material to be carved).Notes regarding shaping of tools with carbide inserts, when using a high speed grinder with a friable grindstone :

|

|

Typical Grinding Media Used

Sharpening the ToolStone working tools should be resharpened at the start of the day, and as needed.As with shaping of tools with carbide inserts, when using a high speed grinder with a friable grindstone, DO NOT cool by dipping in water. This will cause the carbide to crack due to shocks. |

|

Typical Grinding Media Used

Honing the ToolStone working tools should be honed when carving soft stones, especially before the final cuts.Note: When honing or stropping, the side to start on is the one where the grinding was last done. If you start on the other side, the burr will get ripped off and you will probably have to re-grind the edge. Dr. Larrin Thomas’ book, Knife Engineering: Steel, Heat Treating, and Geometry (2025), discusses burr removal quite well. |