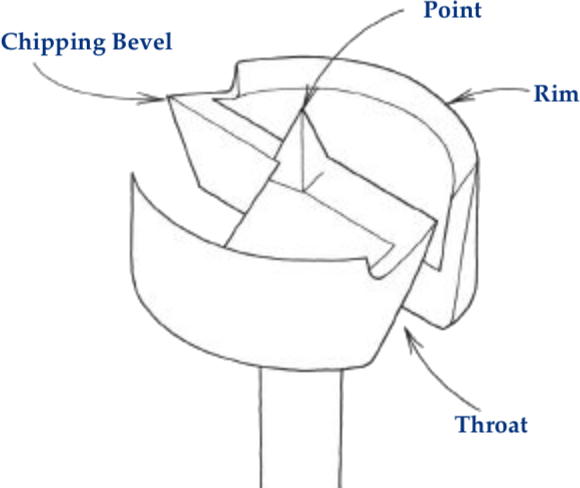

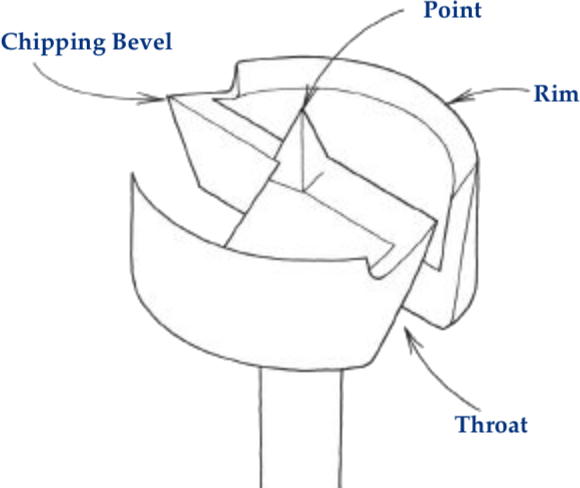

Forstner drill bit edges

The absolute best source for sharpening this tool is Leonard Lee's book, The Complete Guide to Sharpening, Chapter 15. (This is a must-have for any sharpener's library.)

Other notes :

- Rims

- Ensure both rims are the same height.

- Rims can be sharpened using a round or half-round file. I have also used a small sanding drum in a Dremel-style device when the drill bit was badly dulled.

- Sharpen the inside of the bevel (nearest the point), and not the outside. Sharpening the outside would reduce the bit's overall diameter.

- Chipping Bevels

- Ensure both chipping bevels are the same height.

- The chipping bevels should be at the same height as the rims. If there is a significant gap, the drill bit should be replaced.

- Sharpen the throat of the bevel using a flat file, and not the other side. Sharpening the side opposite the throat would reduce the chipping bevel's height.

|

It's the little details that make something look handmade.

Unknown

|

- Point

- DO NOT change the center point of the drill bit.

- Grind the minimum off the point.

- Ensure the point extends beyond the rims by at least 0.005".

- DO NOT change the diameter of the drill bit.

|

General Guidelines

|

|

Point Angle

|

Chipping Bevel Rake Angle

|

Sharp

ness

|

Notes

|

|

30-40°

|

10°

|

|

|

Notes & Comments

Probably best to stay with the drill bit's geometry as supplied by the manufacturer.

Sharpness Scale

Example icon

Sharpness scales (as shown in the grey icon to the left) are used to indicate the recommended sharpness for the blades noted above. You can click on any of the icons showing the sharpness scale and be redirected to the page describing this more. Lower numbers are duller; higher numbers sharper.

These are general recommendations; you will need to use your own judgment, based on the knive’s intended purpose.

More Information

Books & Papers

Videos & Presentations

- Drilling on the Lathe (YouTube video), by Dennis Belcher. This session deals with how to sharpen Forster drills bits, replace a damage MT2 shank on a drill chuck, and choosing a drill chuck.

Web Sites