|

|

General Information on Sharpening

Wood Turning Tools |

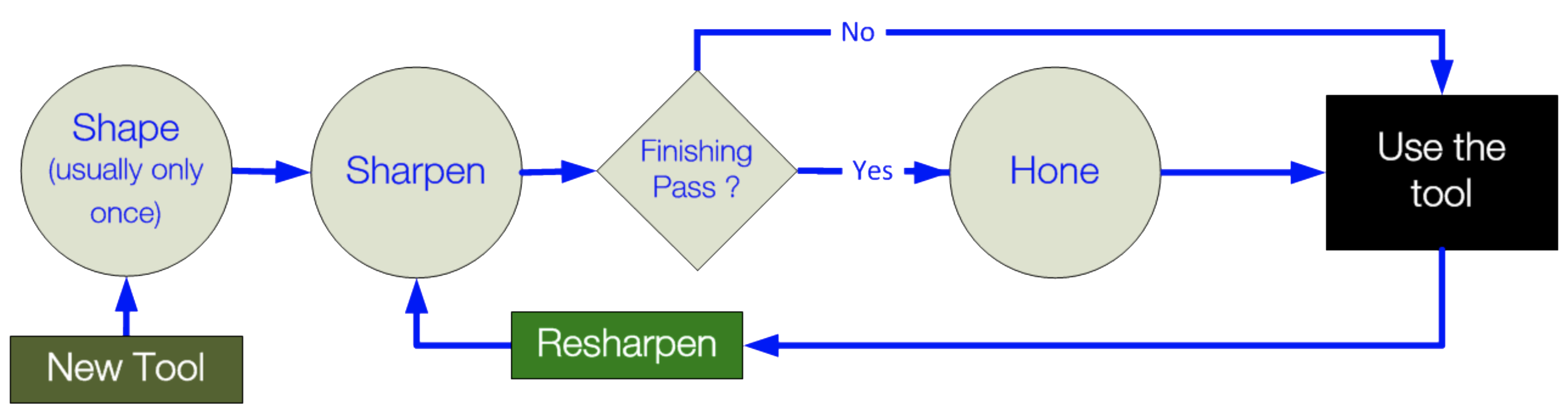

Shaping the Tool - Wood turning tools are typically only (re)shaped once in their lifetime. And that happens when the turner gets the tool from the manufacturer, and adjusts it to their own preferences. |

Sharpening the Tool - Wood turning tools should be resharpened often. Softer woods like cedar don't require that the tool is resharpening as often; but harder woods definitely necessitate the need to be resharpened often. Some turners resharpen as frequently as every 10 or even 5 minutes. And of course, the tool must be resharpened whenever the turner accidentally pushes into the chuck or drops the tool (as it always lands point down !). |

Honing the Tool - Many turners do not hone their turning tools. Then there are others who sharpen and hone; and then they re-hone again as much as possible (rather than resharpening each time). Alan Lacer is a proponent of this approach, using a diamond plate. You can see that demonstrated in the video below by Mark Baker. My experience has been that rough turning can be done using a tool which is not honed; however the final cuts should be done with a tool which is honed. This provides for a smoother surface which requires less sanding (as sanding is the verb form of a 4-letter word !). Also, a well honed tool surface is a great benefit for woods with tight grains or which are very hard. Note: When honing or stropping, the side to start on is the one where the grinding was last done. If you start on the other side, the burr will get ripped off and you can end up with an edge like above. |

|

|

|

AAW Total Experience Woodturning Tip: Honing Tips with Mark Baker from AAW on Vimeo. |

In this series of 8 episodes, Nick Agar, professional woodturner, will show you the special sharpening techniques for all the common woodturning tools. This includes what jigs you should use, how to create different shapes, best practice on sharpening, what grinding wheels you should have as a woodturner, tips, tricks and much more.

| Title | Comments |

|---|---|

| 1. Sharpening Techniques for Woodturners – with Nick Agar – Introduction | In the first episode Nick will give you an introduction to Tormek’s sharpening system and what jigs you’re using when you sharpen woodturning tools. He also goes through how to make the stone flat with the TT-50 Truing Tool, a smart tip when using the SP-650 Stone Grader and finally the perfect grinding wheels for the woodturner. |

| 2. How to sharpen bowl and spindle gouges – Tormek SVD-186 Gouge Jig – with Nick Agar | In this episode Nick Agar shows how you create a fingernail grind on your woodturning gouge and to replicate this grind every time. Nick goes through the procedure step by step using Tormek’s TTS-100 Turning Tool Setter, the SVD-186 Gouge Jig, the SB-250 Blackstone Silicon and the LA-120 Profiled Leather Honing Wheel. |

| 3. How to sharpen roughing gouges, skews & parting tools – Tormek SVS-50 Multi Jig – with Nick Agar | In this third episode, Nick Agar shows how to sharpen a roughing gouge with a few simple steps using the open seat of Tormek’s Multi Jig SVS-50. Further, he shows how to sharpen a parting tool and a skew using the closed seat of the SVS-50. Nick also demonstrates how to use the Tormek Marker Method when setting the angle and how to sharpen a custom skew shape on the side of Tormek’s Diamond Wheel using MB-100 Multi Base. |

| 4. How to sharpen scrapers and cutters – Tormek SVD-110 Tool Rest – with Nick Agar | In this episode, Nick Agar shows how to sharpen a woodturning scraper creating a large burr and a small burr depending on the material you’re working in. He uses the Tormek SVD-110 Tool Rest and the DF-250 Diamond Wheel Fine. In addition, Nick demonstrates how to sharpen small hollowing cutters and ordinary cutters using SVD-110 and SVD-186. |

| 5. How to sharpen on the side of the Diamond Wheels – Tormek MB-100 Multi Base – with Nick Agar | Nick Agar, will in this episode show you how to sharpen a custom skew on the side of Tormek’s Diamond Wheel create a completely flat bevel. He is using the SVS-50 Multi Jig and sharpens on the DF-250 Diamond Wheel Fine with the MB-100 Multibase. |

| 6. Tormek’s Grinding Wheels for the Woodturner – with Nick Agar | Nick Agar, professional woodturner, goes through the different grinding wheels available for the woodturner and what advantages they have. He’s showing the Tormek Grinding Wheels; SG-250 Original Grindstone, SB-250 Blackstone Silicon, DC-250 Diamond Wheel Coarse, DF-250 Diamond Wheel Fine and DE-250 Diamond Wheel Extra Fine. |

| 7. Tips & Tricks – Sharpening Techniques for Woodturners – with Nick Agar | Nick Agar, professional woodturner, gives you his best tips and tricks when sharpening woodturning tools with Tormek’s sharpening system. Amongst the tips are how you find the correct bevel angle on your tool, how to make the edges of the grindstone smother, how to remove steel particles from the Leather Honing Wheel and how to clean the rubber drive wheel. |

| Woodturning from Inside of the Bowl – Unique Shot Never Seen Before – with Nick Agar | Together with professional woodturner, Nick Agar, we can now show you how it looks from inside of the bowl when woodturning. This angle has, as far as we know, never been filmed before. Enjoy! 😊 |